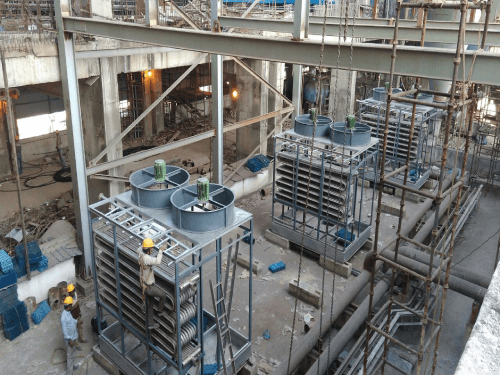

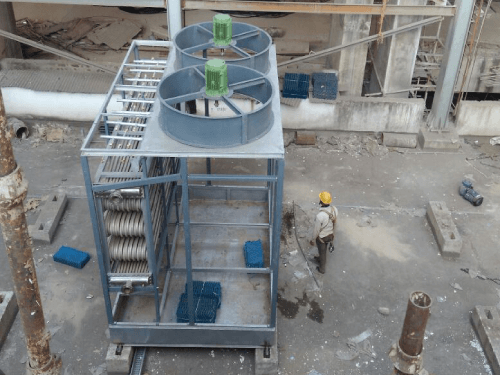

Closed Circuit Cooling Tower Manufacturers in India

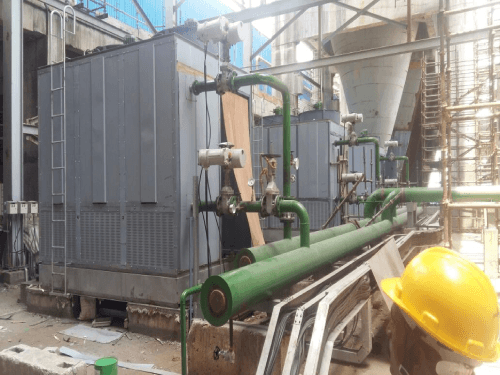

Closed Loop Cooling Tower / Closed Circuit Cooling Tower operates in a manner similar to conventional cooling towers, except that the sensible heat to be rejected is transferred from the process fluid to water and ambient air directly through a heat exchange coil. The coil serves to isolate the process fluid from outside environment, keeping it clean and contamination free in a closed loop, thus creating two separate circuits

- Primary / Internal circuit in which the process fluid circulates inside the coil.

- Secondary / External circuit sprays circulating water from the basin over the coil which evaporates to reject heat to the environment.

Why Choose

Features of Natural Draft Cooling Tower

- No requirement Fan, Motor and PVC fills.

- Power saving (no power consumption to induce air flow- no fan).

- Low maintenance

- FRP louvers reduces spillage and evaporation loss

- Hot Dip galvanized structure and S.S fasteners increase the life time and efficiency of cooling tower

- Can be installed for any range of cooling applications

- Non clog nozzles & Easy to Clean

- Environmental Friendly

- No Mechanical Noise & Safety of operation

Contact us for more information

The Natural draft cooling tower particularly pretty as a cost-saving solution for power plants and other industrial plants requiring larger quantities of cooling water. Natural Draft cooling tower operates without fans and Fills, the large amount of electric power or else required for large cooling tower systems is not required. The mandatory cooling air is pass on through the tower by natural draft henceforth neither fan nor fan power is required for these kind of Cooling Solution. No maintenance required like other Wet (or) Dry Cooling Towers. By using of Non clock nozzle are easy to cleaning reduce spillage and evaporation loss. Hot Dipped Galvanized Structural’s and S.S.fasteners increase the lifetime as well as the efficiency of the cooling tower it can be installed for any range of cooling application.

Our Clients